Ensuring Load Handling Safety: Anti-Sway Devices

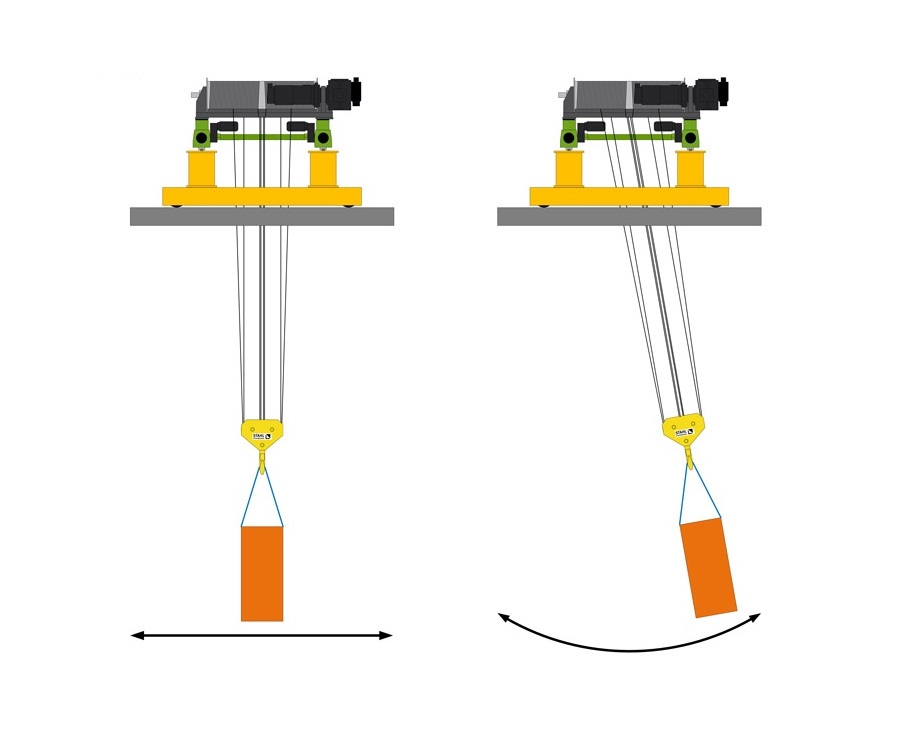

Anti-sway devices are technological solutions developed to prevent uncontrolled load swinging and make handling processes safer. These devices work based on physical principles and mathematical calculations to maintain load balance and minimize swinging motion.

Anti-sway devices typically consist of components such as sensors, control systems, and motors. Sensors monitor the real-time status of the load, which is analyzed by a control system. Adjustments are then made via motors to correct any unwanted load sway. This allows load handling operations to be carried out more quickly, safely, and efficiently.

Another advantage of anti-sway devices is their ability to be integrated into existing handling equipment. By adding additional hardware to existing overhead cranes or gantry cranes, anti-sway features can be easily incorporated. This enables businesses to make their current infrastructure more efficient while avoiding significant costs.

Anti-sway devices are an essential tool for improving load handling processes in the manufacturing and distribution sectors. Understanding their theoretical principles, evaluating their practical operation, and integrating them into existing equipment can help businesses achieve safer, faster, and more efficient load handling operations.