Horizontal Skew Prevention Technology: The Role of Anti-Skew Systems

In industrial sectors, material handling and lifting operations are quite common, and one of the issues encountered in these processes is horizontal skewing. Horizontal skewing can cause loads to move irregularly and handling equipment to drift into undesired positions. Anti-skew systems, developed to address this issue, play a crucial role in enhancing safety and efficiency in load handling processes.

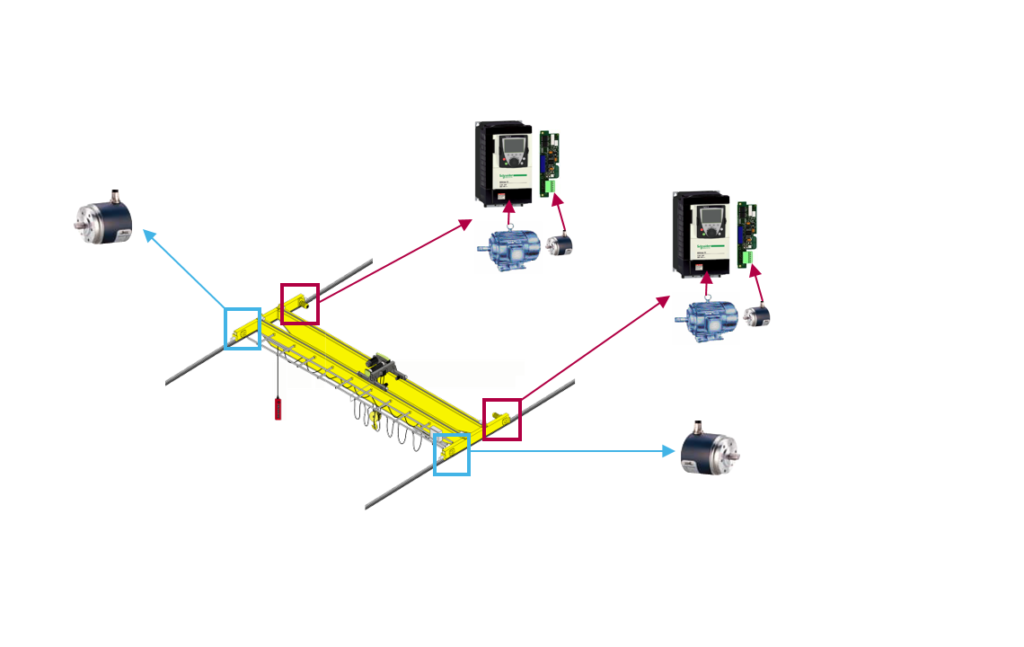

Anti-skew systems are designed to prevent or minimize horizontal skewing. These systems typically consist of components such as sensors, control units, and motors. The sensors continuously monitor the position of the crane, and the control unit analyzes the data, allowing the motors to make adjustments to protect the load from unwanted horizontal movement.

Anti-skew technology is commonly used in equipment such as cranes, conveyor systems, or transport carts. Particularly in cases where sensitive materials are being handled or where high safety standards are required in industrial facilities, anti-skew systems make operations safer and more controllable.

The use of anti-skew systems can eliminate horizontal skewing issues, thereby improving business efficiency. These systems can also reduce equipment damage, enhance workplace safety, and make production processes more reliable. Additionally, the integration of anti-skew technology can extend the lifespan of equipment and reduce maintenance costs.