Spare Part – Busbar and Equipment

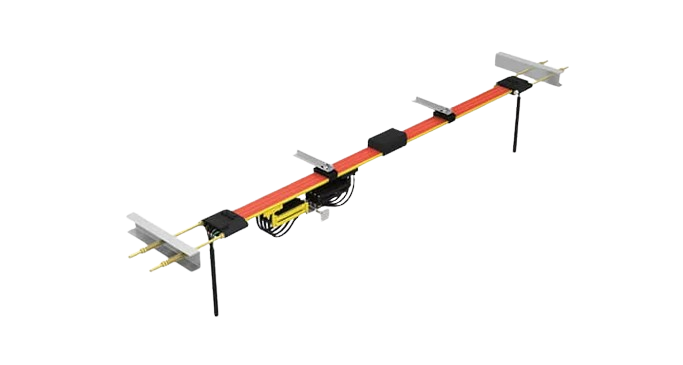

In crane manufacturing, closed busbar systems are critical components for ensuring efficient and safe energy distribution. Designed with advanced technology, these systems provide the flexibility and convenience required by modern facilities, delivering reliable power distribution.

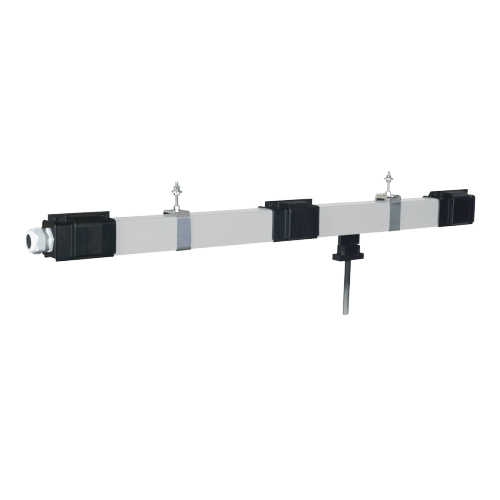

These busbars are constructed with a PVC body and feature copper conductors installed within. Standard busbars are produced in 4-meter lengths and can be easily connected every four meters with practical joint systems. Additionally, they are available in custom lengths as needed. With the correct amperage selection, a single busbar line can power multiple crane systems, enabling efficient energy distribution in large facilities. Maintenance and component replacements are straightforward, which reduces operating costs.

Replacing traditional cable systems, closed busbar systems offer significant cost and installation advantages. Their modular and prefabricated structure allows seamless integration into any project, eliminating issues like high costs, lack of flexibility, and challenges with current distribution at specific points found in traditional systems.

These systems are available in 50 A, 75 A, 100 A, 150 A, and 200 A options, meeting the diverse power and current needs of crane systems. This range of choices provides adaptable solutions for cranes with varying power and current requirements, ensuring efficient and tailored energy solutions across different setups.