Spare Part – Beam Electrical Installation

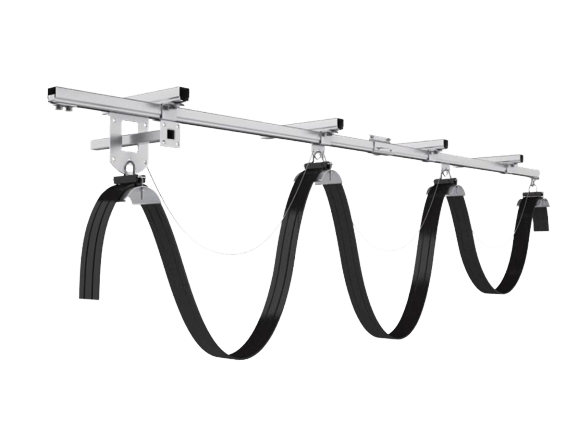

C Profile and NPI80 Systems

The C Profile is commonly used for transporting flat rubber cables involved in crane lifting and traversing operations. As the cable cross-sections increase for high-tonnage systems, NPI80 tracks are preferred over the C profile due to their capacity to handle larger, more robust cable setups.

Here are key components in these systems:

- Steel Cable Trolley: These components enable the movement of cables within the C profile channel, synchronized with crane movements.

- Fixed Cable Trolley: Used at the start of the line to prevent cables from exiting the channel, maintaining system stability.

- Lead Cable Trolley: This final trolley directs the entire cable system’s movement via a sliding arm, coordinating with crane motions.

- Pendant Lead Trolley: Used for pendant cable connections in independent control systems.

- Connecting Elemnts: These facilitate continuous connections between C profiles of varying lengths.

- Fixed Hanger: Secures C profiles onto the crane girder’s angle brackets.

- Profile End Cap: Prevents lead trolleys from exiting the C profile at the end of the channel.

These components are essential for reliable cable management, allowing cranes to perform complex movements without interruptions in power or control.